General reasons for the damage of flexible rubber expansion joints

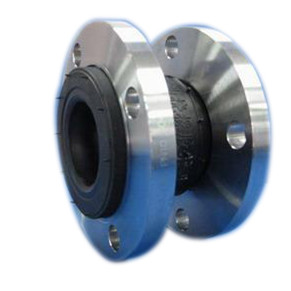

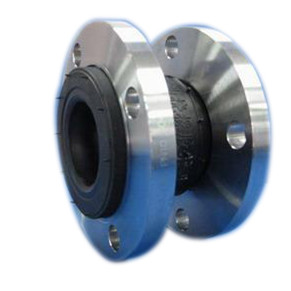

- The flexible expansion joint is the only vibration reduction equipment installed in the pipeline, not only to withstand the pressure of the whole pipeline, but also to protect the flexible expansion joint as a protective device. Usually in the understanding of the specific pressure range of the site, the choice of one or more layers of stainless steel wire woven. General flexible expansion joint work pressure is divided into 5 levels: 0.25, 0.6, 1, 1.6, 2.5Mpa.

1.Rubber expansion joint damage analysis: rubber expansion joint in the running for some time, the inner layer is wear and corrosion, the pressure capacity of the entire rubber expansion joints decreases, stainless steel wire in contact with the media sphere, in which the chlorine ions after the serious corrosion of stainless steel mesh, leading to corrosion of stainless steel wrapped around the outer layer weaken, pressure in the pipeline to a certain extent, spill just happened。

2.Rubber of rubber expansion joint, after a period of time to reverse the spiral wound stainless steel highlights a glitch. Not only left a great legacy of the maintenance personnel at the time, but will be more severe colloid surface damage, causing the whole sphere fracture.

3.In the end, because of the influence of the material, the use of the environment, the medium of the pipeline, the artificial maintenance and other reasons, the service life of the rubber expansion joint is also different. In the installation of rubber soft joints, if the installation method is not correct, it may cause damage to the rubber soft joint. For example: rubber joints in the outdoor weather exposure, frozen, wind, sand, rain and snow erosion; beyond the scope of tensile; use of excessive grinding joint strength discounts and other causes may cause damage to the soft rubber joints.

www.masonhn.com

.png)

.jpg)